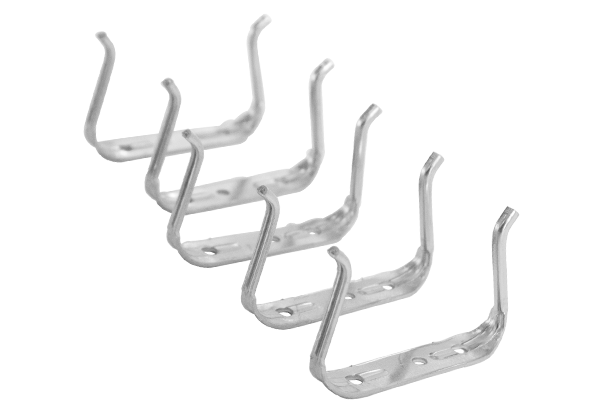

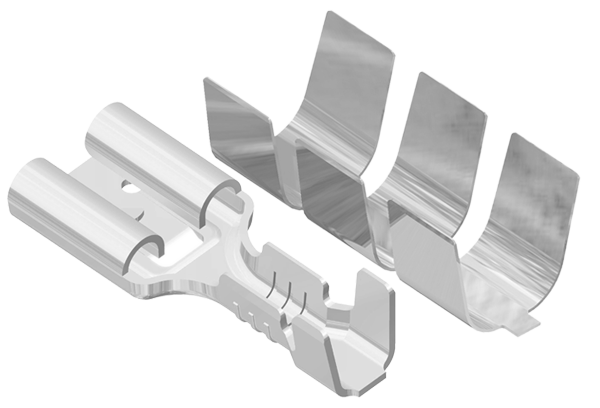

FIXING COMPONENT FOR THE AUTOMOTIVE INDUSTRY

Industry: Automotive

Customer need: a European producer of technologies in the radio frequencies industry, need to develop a particular metallic structure which is flexible, but at the same time able to withstand vibration, with multiple functions including integrated mechanical fastening to a component with a high electronics content for the automotive industry.

GMG proposed solution: the initial idea, which then proved successful given the complexity of the geometry of the object and the strong ability to spring back along the stamping phases, was to give the utmost importance to the raw material and thus propose a special high-resistance material, processed with targeted technologies by a selected North-European supplier.

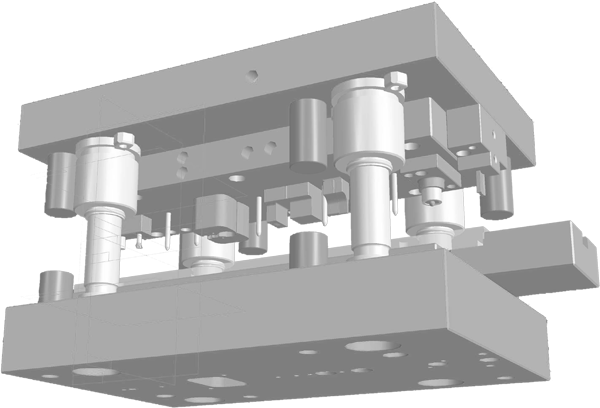

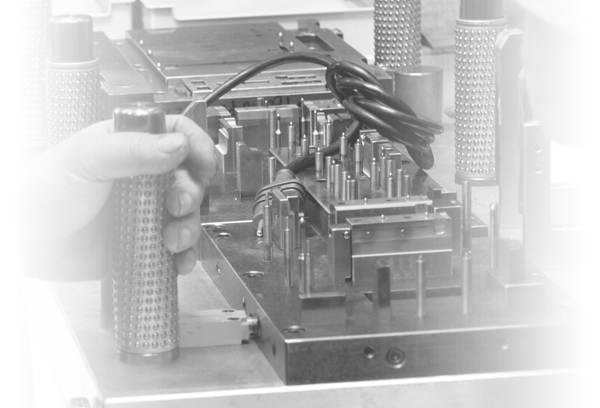

How to obtain the result: The development of the project has seen the study and gradual perfection of some phases, through pre-testing in the initial phase and subsequent tests, considered crucial for the success of the object and the reliability of the supply. In particular, it was chosen to distribute the more invasive processing all along the progression of the mould, so as to balance the efforts for a mould of these large dimensions, and at the same time manage in a controlled manner the spring back of the material which, if not governed at each stage, risks compromising the final geometry of the item, especially in the closing of the upper fixing component (as per the photo). This project has seen the engagement of an internal technical-quality team, constantly in communication with the customer's team from the co-design phase to the development of the final changes in the production phase, with the objective of obtaining a reliable mould and product, made possible thanks to a single stamping progression, without extra-processing for later recovery.