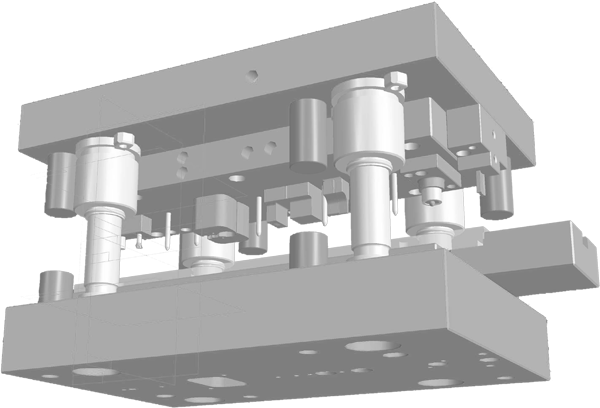

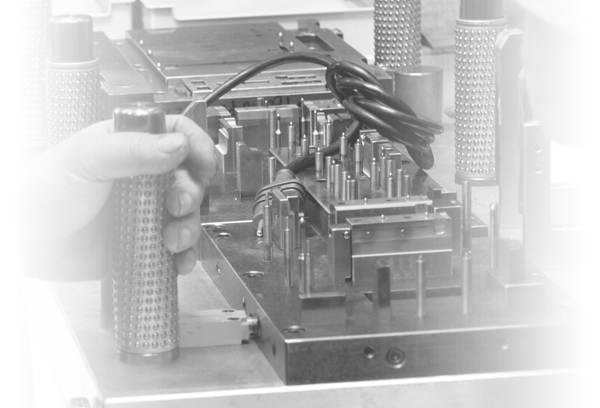

Construction and maintenance of the moulds

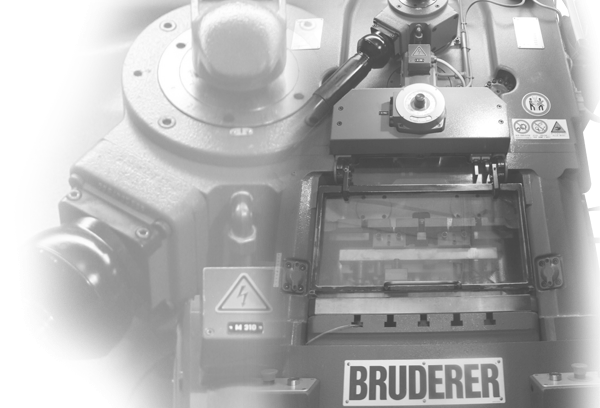

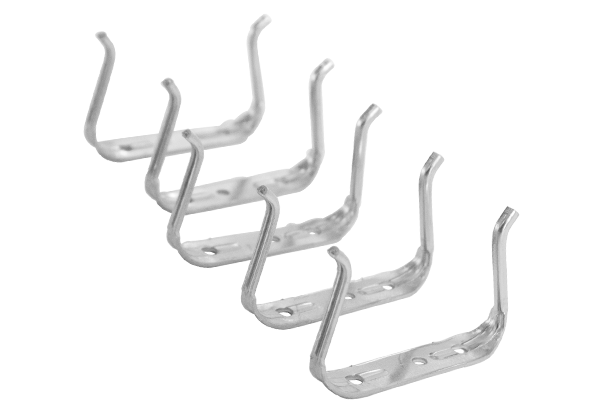

Our internal equipment, in contact directly with the technical department and the industrialisation of the product, is organised efficiently so as to build moulds for custom projects, to also perform routine maintenance operations and extraordinary restoration operations of moulds in production.

The strategic decision to invest and develop our internal tooling over time allows us to be responsive in normal maintenance operations, and especially in the optimisation of testing and in the pre-series, which is a decisive step to reliably responding to the market and standard productions according to the expectations of the customer.

The strategic decision to invest and develop our internal tooling over time allows us to be responsive in normal maintenance operations, and especially in the optimisation of testing and in the pre-series, which is a decisive step to reliably responding to the market and standard productions according to the expectations of the customer.